A Case With Character: Building With Bronze

Each bronze Black Bay watch leaves TUDOR’s Geneva manufacture the same rich golden color, sitting somewhere between the colors of yellow and rose gold.

Human beings have been making tools out of bronze for nearly 2,500 years – and for good reason. Bronze is very hard, can withstand extreme temperatures, and is resistant to corrosion from saltwater, which covers 71% of our planet. Bronze, quite literally, changed the course of human history. It was discovered in mid-4th millennium BC and used to fashion helmets and armor, and later in history, bronze alloys were used in naval applications for centuries, making corrosion-resistant ship components like propellers and hulls, and even damage-resistant navigational instruments. It’s also used in armored vehicles, tanks, and submarines for its strength and robustness.

Metals like stainless steel and titanium dominate when it comes to tool watches, but bronze still offers its own unique combination of advantages and character that set it apart. And it’s for these reasons that TUDOR embraces bronze for watches like the Black Bay Bronze and Black Bay Fifty-Eight.

Bronze is a copper-based metal and alloys typically include a significant percentage of tin, depending on the application of the specific alloy. When it comes to watches, TUDOR created a proprietary alloy that is high in aluminium, slightly reducing the metal’s weight while also stabilizing it for long term durability and aesthetics.

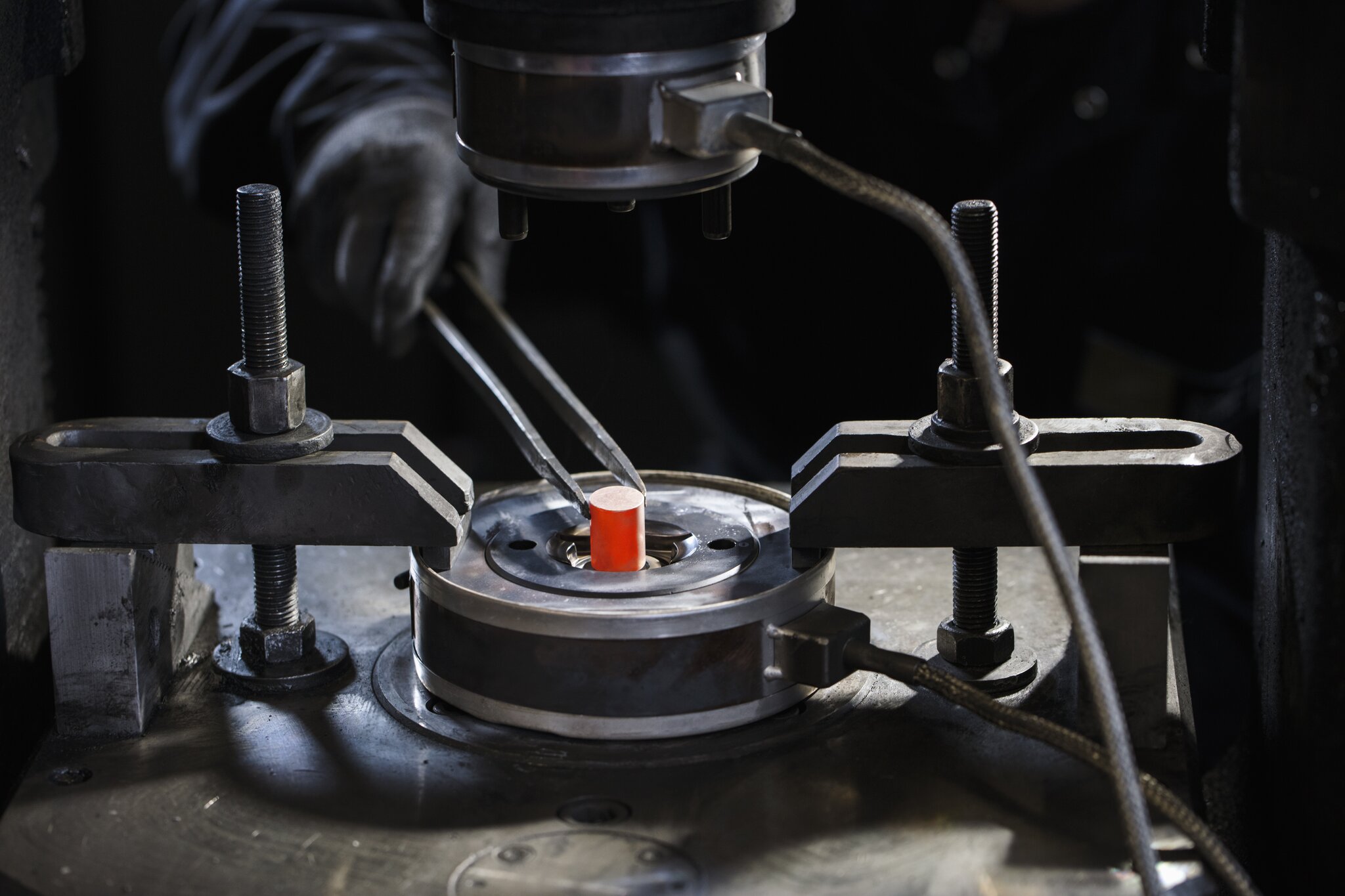

This alloy required TUDOR to develop special production processes to achieve the level of precision necessary to make watch components and to ensure that the final products would provide years of uninterrupted pleasure to customers. Once the special aluminium bronze alloy is produced, it is made into long bars and then cut down into small cylinders that can be worked into cases. That process involves heating the cylinders to roughly 800 °C and then stamping each cylinder individually into the rough case shape. There is a very narrow window when the case can be stamped out of bronze at such a high temperature, and during this phase precision is key. A few degrees too hot or too cold and the case will be ruined. This is done with a friction screw press and requires many tonnes of force to achieve. From there, more than 40 additional steps – many completed by hand – are required to hone the shape, add threads for the caseback and crown tube, apply the various brushed and polished finishes, and drill the lug holes.

Making all of this even more complicated is the fact that bronze quickly develops patina from its surrounding environment. Things like ambient moisture and the oils from human hands start to add character to its golden hue, leaving traces that can range from slight shifts in color to full-on blue, green, and purple tones. As TUDOR craftspeople shape each component, the utmost care is required to prevent any discoloration so that each customer’s watch arrives ready to take on a patina unique to them. Gloves are always used when handling bronze components and the watches must be rigorously dried after passing waterproofness tests.

If all of this sounds like a lot of work and a lot of care, that’s because it is. Crafting bronze watches is not easy. But it is the final outcome that makes it all worth it and results in bronze Black Bay watches unlike any others.

Each bronze Black Bay watch leaves TUDOR’s Geneva manufacture the same rich golden color, sitting somewhere between the colors of yellow and rose gold. But as soon as each customer takes his or her watch home, the bronze will begin to transform according to ambient conditions. A watch worn day-in, day-out by the seaside and a watch worn only occasionally in the desert will take on vastly different shades and degrees of patina, giving the watch a special personality that couldn’t be created or replicated in a workshop.

This is the romance of bronze. All the research and development, all the history, and all the hand craftsmanship results in something more poetry than science. Each watch becomes more and more unique to the wearer over time, providing decades of enjoyment and acting as a reflection of a life well lived. All that work is worth it.

Watches mentioned

Related articles

View all news

SRAM and Tudor Pro Cycling Craft a Masterpiece in Le Locle

Yes, there’s a watch—but that’s not the only masterpiece involved at the Tudor Manufacture.

#craft

Dissecting the Details of the TUDOR Bronze Bracelet

For the first time ever TUDOR has produced a bracelet entirely made from bronze.

#craft

The "How" of Hands

A detailed look at how TUDOR Snowflake hands are produced.

#craft

These 1950s Ads Shed Light On TUDOR’s Guiding Principles

The “Trial of Destruction” as campaign tells you everything you need to know about what drives TUDOR to make the toughest watches possible.

#craft